Fabrication Services

Using state of the art machinery combined with a time served coded welding fabrication team Expervent can produce a wide range of fabricated bespoke items to suit your requirements.

Our in house design engineers can visit site and produce detailed CAD site layout drawings before producing detailed manufacturing drawings for your approval.

We are able to manufacture 1 off bespoke individual items or full turnkey design packages dependant on your individual requirements.

Our large modern manufacturing facility is equipped with a range of fabrication plant and has the capacity to manufacture a vast range of items working with all types of metals with thicknesses up to 10mm.

Our services include:

- Genral Fabrication

- CNC Machining

- CNC Press Braking

- Coded Welding

- Laser Profiling

- Plasma Cutting

- Section Rolling

- Spray Painting

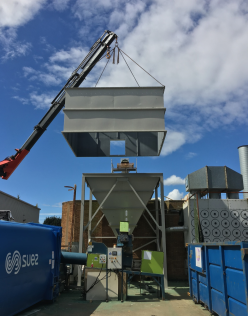

Once approved the hopper & steel framework were fabricated & fully welded before being finished at a our paint spraying facility in RAL 7032 pebble grey to suit the clients requirements.

The fabricated sections were then loaded onto a dedicated transport complete with cranage before being installed onsite.

The project from drawing approval, through fabrication to installation was complete within four weeks working closely with the client to ensure the installation had no impact on site production or facilities.

Expervent complete the manufacture and installation of a 5.2m x 9.3m steel plant deck to a major manufacturing facility in the north east of england.

Our CAD engineers produced detailed drawings for approval before the deck was fabricated from fully welded mild steel sections with a hot dip galvanised finish to the clients specifications.

Expervent complete the installation of a new grinding & linishing area L.E.V dust control system within a major furniture manufacturing facility.

The system included the design, manufacture and installation of four bespoke L.E.V extract hoods capable of capturing the dust particles produced by the mild steel grinding & linishing activities on site.

Following the installation the facility was visited by the health & safety executive who confirmed that the L.E.V system design conformed with the requirements of HSG 258 and the L.E.V service report and log book were present.

Contact Expervent on 0191 489 5400 / enquiries@expervent.com

for your free no obligation survey.